OPERATIONS

Our Operations Team is tasked with the crucial role of transforming engineering designs into tangible products. This process can involve either in-house manufacturing or external procurement, leading up to the assembly of components into power units. Unique in comparison to operational teams in other industries, our working environment is characterised by low production volumes, high precision requirements, rapid changes, significant complexity, and critically short lead times. This creates a dynamic and challenging environment that offers rewarding work experiences for our team who are firmly at the centre of our successes.

MANUFACTURING ENGINEERING

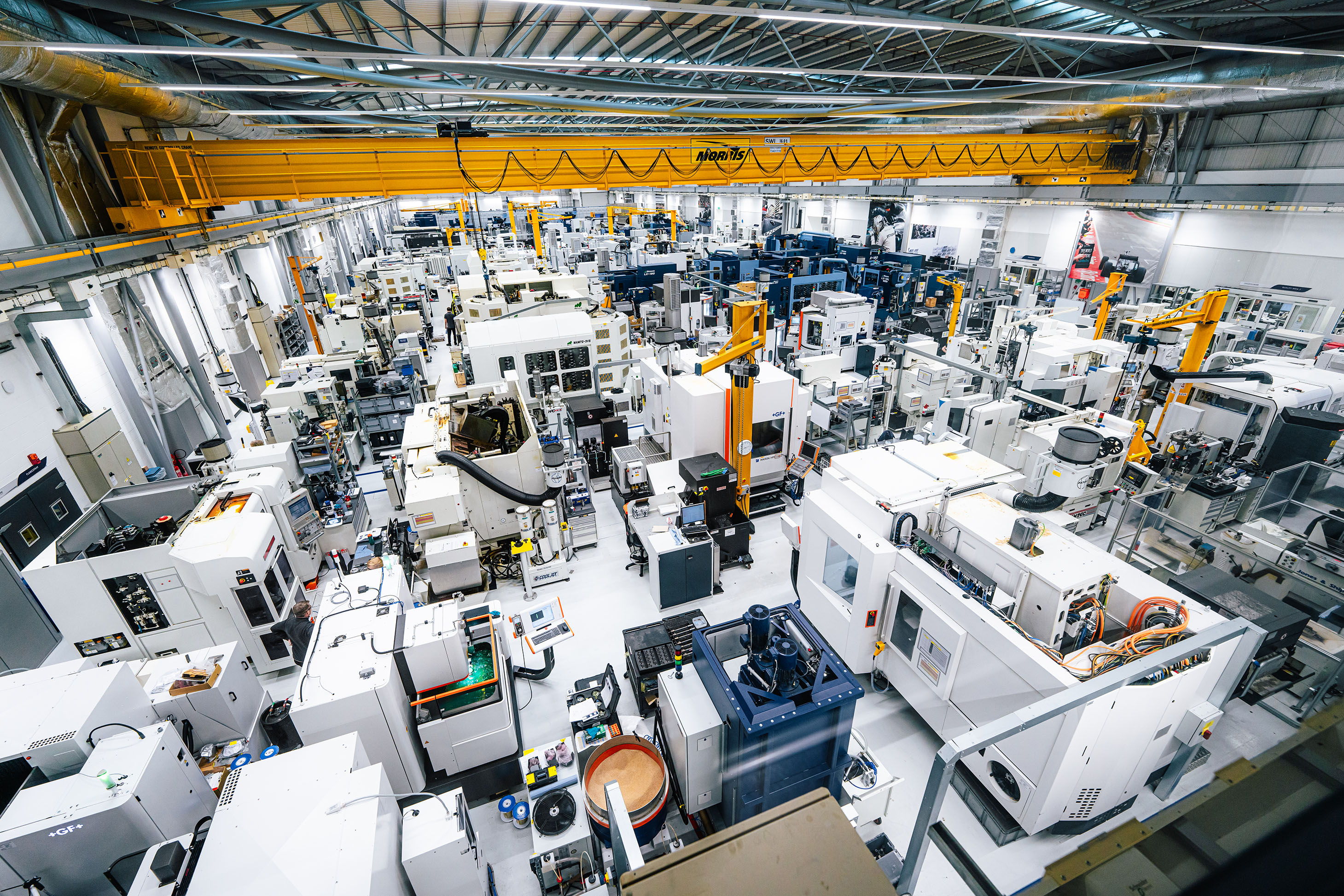

& MANUFACTURING

Mercedes AMG High Performance Powertrains has the capacity and expertise via its many dedicated production systems to deliver complex power unit components at speed and to the highest standards. Manufacturing Engineers are responsible for taking engineering models and drawings to define the Manufacturing processes, utilising our vast range of high-tech machine tools, equipment and assembly functions. The various manufacturing teams then execute the processes with a high degree of precision to ensure the highest quality in the final products.

QUALITY

Working in an environment where even the smallest detail can significantly impact performance, the role of our Quality Department is crucial in ensuring that all in-house manufactured and externally sourced parts meet the required quality standards.

When inspecting parts, the department employs a range of metrology approaches, including Coordinate Measuring Machines (CMM), x-ray inspection, and other advanced techniques. This is all supported by a suite of best practice processes to maintain consistent quality and reliability.

Build / Assembly

The Build Team at HPP is tasked with the assembly, servicing, and disassembly of powertrain components, sub-assemblies, and full power units. These tasks are performed ahead of in-house testing, track testing, and race programmes. Despite sounding straightforward, this work can be incredibly complex, detailed, and precise. The Build Team’s meticulous efforts ensure the reliability and performance of the power units, which are critical for success on the track. Additionally, working in this department is one of the more common pathways for pursuing a career in the F1 pit lane, providing invaluable experience and skills for aspiring F1 professionals.

Q & A Darren – Build Team Leader,

Build/Assembly Business Unit

Please share an overview of what you do in your day-to-day role?

I currently lead a team of 12 Assembly Technicians, including apprentices, helping to develop and build future performance development powertrains in readiness for large rule changes 2026.

What is your team responsible for?

My team is responsible for the final assembly of all development power units including single cylinder, V6 and many type of rig power units. We support initial builds, rebuilds, development specification changes in build or mid sequences on dyno. Alongside the builds, the team help to define and develop build processes and workshop improvements with a common goal of Mercedes success for 2026 and beyond in F1.

Please could you give us a brief overview of your career path?

My career in motorsport started at the age of 14 working in the lower formula’s during weekends, working my way up the formula’s (Formula ford / Formula Vauxhall / Formula 3). After school and college, I joined Zytek Motorsport as an Apprentice Engine & Trackside Technician working in F3000. I was thrilled to then get the opportunity to fulfil my childhood dream of working in F1 at Mercedes-Illmor. I started here in February 2005 working in F1 Engine Strip / Final Inspection on the last of the V10 engines, shortly after I moved onto the Assembly Team starting in Cylinder Head Build on the F1 V8 project. At the end of 2006 I progressed into Final Engine Build where I stayed until 2009. After a short break from HPP pursuing my own business venture, I returned in 2011. I joined the V6 Turbo Build Team helping to build the new MGUH assemblies ready for the 2014 season before a return to Final Engine Build and Trackside Rotation. I supported at the racetrack as a Rotating Engine Technician from 2015 – 2019 mainly for Mercedes Grand Prix however I also supported a few events with Manor F1 and Force India during tests and races. 2020 I helped assemble the CPAP units during the Covid pandemic, before we swiftly returned to F1 duties. I started my current role in July 2021 as Performance Development – Build Team Leader. Alongside this role I completed the Future Team Leader apprenticeship

course recently completing with distinction.

What has been the highlight of your career so far?

There have been many highlights so far for me at HPP, being involved in several dominant driver and constructor championships. Singling out one is very difficult however working on Lewis Hamilton’s car during the 2015 & 2016 seasons were certainly up there for me! Although the 2019 Valentino Rossi and Lewis Hamilton Monster energy event was very special too! I am hopeful there are many more highlights to come as we all push towards success in the future.

Whats the most challenging aspect of your role?

The most challenging aspect of my role is the ability to switch off, the day is never over at HPP and the constant drive for success can be challenging at times. On the flip side the rewards we see in the form of HPP successes can make this an easier challenge to deal with.

What tips would you give someone who wants to pursue a career in your team?

If I could give tips to someone who is looking to join the Development Team, I would suggest a positive attitude towards all tasks no matter how small, learn whatever you can from all team members, and be open minded towards change. Always remember to treat people how you would like to be treated.

ASSEMBLY SYSTEMS

Despite the high-change and flexibility needed within the operations environment, there is also a crucial need for high precision and repeatability in tasks. This is where the Assembly Systems department excels, designing and developing revolutionary manufacturing processes that simply cannot be bought off-the-shelf. By building our own special purpose automation machines, robotics, and tooling, we can leverage a competitive advantage by developing the product and process concurrently.

TRANSPORT & LOGISTICS

The logistics aspect of the supply chain is critical to HPP’s success, ensuring that the right parts are delivered to the right place at the right time. Our team is also responsible for managing the logistics of power units and freight worldwide, supporting the Formula 1 races and track events. This complex operation is essential for enabling seamless performance and competitiveness at HPP.

PURCHASING

The Purchasing team at HPP is vital to our supply chain, ensuring that all the components and services are delivered on time, at the right quality, to the appropriate stakeholder’s requirement and at the correct value for money. This department is integral to HPP Operations serving as the connection between the company, the internal stakeholders, and the external partners. The attention to detail, accuracy, and the capability to meet complex and demanding needs are key features of this team.

GOODS INWARDS AND INTERNAL LOGISTICS

Goods Inwards and Internal Logistics are responsible for the accurate, safe, and secure handling and storing of our parts. Attention to detail, efficiency, organization, and a positive attitude towards customer demands are the main characteristics of this department. This team ensures that every part is meticulously checked, stored correctly, and ready for the Build department when required. Their responsiveness to customer needs is essential in supporting the success and smooth operation of our supply chain.

PROGRAMME MANAGEMENT

In such a dynamic, fast-paced and deadline critical environment, a strong Programme Management team is essential for delivering performance and reliability to the circuit. This involves overseeing all programmes end-to-end; from high-level strategies, to the detailed aspects of engineering design schedules, seamless flow of hardware, and the delivery of experiments. Successful programme management is built on a foundation of transparency, high attention to detail, and strong interpersonal relationships. These elements ensure that all aspects of the programme are coordinated swiftly and effectively, better and faster than anyone else on the grid.

FACILITIES

The Facilities department at HPP covers a broad range of activities and services to ensure a conducive environment for success. This department is responsible for maintaining buildings and machinery, providing electrical and mechanical infrastructure (inc. complex high voltage systems), setting and managing the Sustainability Agenda and managing on-site amenities such as the subsidised restaurant, on-site gym, waste recycling and landscaping. Their work ensures that all aspects of the physical environment support the team’s needs and contribute to overall productivity and well-being whilst remaining a good corporate citizen within the local community.